|

1.

2. |

Insert the cable ends through the V of each limb (figure

2).

With

the jackscrew adjusted approximately 1" out (figure

1, B), pull the cable through the adjustable end

piece until there is no slack in the cable (figure

1, A).

Note:

If the bow is to be completely disassembled the

jackscrew will need to be started approximately 1/2" to

1" from its fully extended position. |

|

|

|

|

3.

4. |

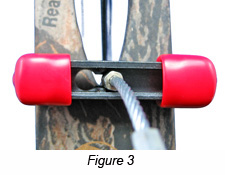

Slide

the cable stop (figure 1, A) completely over to the end

of the slot in the adjustable cable end, making sure

that it is seated properly past the indents (figure

3). Slide

the cable stop (figure 1, A) completely over to the end

of the slot in the adjustable cable end, making sure

that it is seated properly past the indents (figure

3).

Inspect the cable before each use. If there is any

sign of damage, such as a fray, the cable must be

replaced immediately. Never use the Bowmaster with

a damaged cable. Contact us directly for

replacement cables.

|

|

5. |

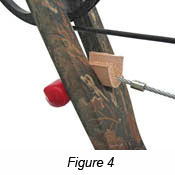

Fold

the leather pads supplied in half and place them in the

V of each limb between the Bowmaster cable and the limb

(figure 4). Fold

the leather pads supplied in half and place them in the

V of each limb between the Bowmaster cable and the limb

(figure 4).

CAUTION:

Position the Bowmaster at least 4" from the last stop

(Figure 1, C) before compressing the bow, otherwise the

stop may be pulled into the cable roller resulting in

damage to the cable roller and cable.

|

|

6. |

Turn

the jackscrew clockwise until the tension is adequately

removed from the sting and cable to perform the repair.

The 5/8" hex head on the end of the jackscrew permits

the use of a wrench or socket driver to make the job

even easier.

|

|

7. |

When

the repairs are complete, check the string and cables

for proper position, then turn the jackscrew counter

clockwise to restore tension to the string and cables.

|

|

! |

WARNING:

The limbs of a compound bow are under extreme tension.

Use caution while working on the bow. Keep the

face of the limbs away from you at all times. Eye

protection must be worn.

|

|

|

Note:

With proper maintenance, the Bowmaster will give years

of dependable service. The Jackscrew, thrust

washer and cable should be kept well oiled.

All-purpose or machine lubricating oil should be used.

Allow the oil to penetrate into the strands of the cable

before removing excess oil. |